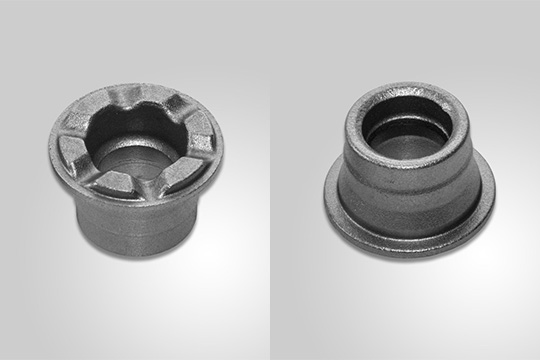

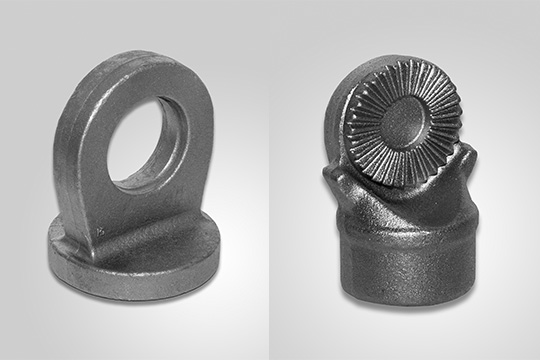

Czym się zajmujemy?

Przedmiotem działalności Kuźni Polskiej S.A. jest produkcja najwyższej jakości odkuwek matrycowych łącznie z obróbką cieplną i mechaniczną dla przemysłu motoryzacyjnego, a także dla armatury, automatyki, lotnictwa oraz budownictwa. Ponadto specjalizujemy się w produkcji odkuwek do urządzeń ciśnieniowych, które spełniają wymagania dyrektywy dotyczącej urządzeń ciśnieniowych 2014/68/UE. Nasze procesy produkcyjne opierają się na wielkoseryjności i powtarzalności wyrobów, jednocześnie zapewniając dostawy „just in time” w ilościach dostosowanych do aktualnych potrzeb Klienta.

Misja firmy

Misją Kuźni Polskiej jest dostarczanie odkuwek matrycowych i wyrobów obrobionych mechanicznie, zgodnie z jakościowymi oraz prawnymi wymaganiami rynku globalnego z poszanowaniem środowiska naturalnego oraz bezpieczeństwa naszych pracowników, przy jak najwyższym wyniku energetycznym.

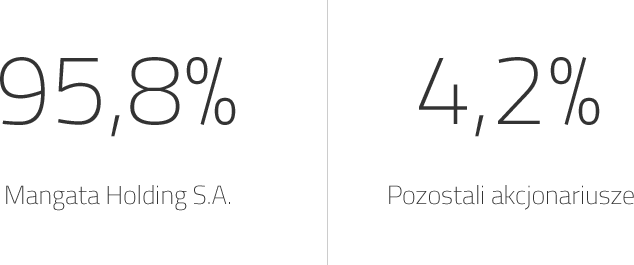

Struktura własnościowa

Zarząd

Leszek Targosz

Wiceprezes Zarządu, Dyrektor Handlowy

Bartłomiej Kadłubicki

Członek Zarządu, Dyrektor Finansowy

Historia firmy

Historia hutnictwa i kuźnictwa na ziemi cieszyńskiej sięga XVIII wieku, kiedy to ziemie te dostały się pod panowanie Marii Krystyny córki Marii Teresy i księcia Albrechta Kazimierza saskiego.

1771 – 1772

Otrzymano pierwszą surówkę w Ustroniu.

ok. 1823 r.

W dziesięć lat po założeniu huty, jej produkcja wynosiła około 210 ton żelaza co stanowiło prawie 40% ówczesnej produkcji hutniczej całego Śląska Austriackiego.

1906 r.

Przekształcono jednoosobową dotychczas formę własności całego przemysłu hutniczego Komory Cieszyńskiej w Spółkę Akcyjną “Austriackie Towarzystwo Góniczo-Hutnicze”.

1912 r.

Sprzedano pozostałe ustrońskie zakłady wraz z majątkiem wiedeńskiej spółce akcyjnej “Brevillier – Urban”, która w okresie międzywojennym funkcjonowała pod nazwą “Austriacka Spółka Akcyjna – Towarzystwo Akcyjne

dla Fabryki Śrub i Wyrobów Kutych Brevillier S-ka i A.Urban Synowie w Ustroniu”. Wznowiona została produkcja dla rolnictwa i kolejnictwa, a w czasie I wojny światowej rozpoczęto produkcję zbrojeniową.

dla wojska. W latach trzydziestych XX wieku, w kuźni rozpoczęto produkcję imadeł, pieców trwałopalnych, maszyn i odkuwek motoryzacyjnych. Do kucia stosowano młoty sprężynowe lub deskowe napędzane transmisją.

1928 – 1939 r.

Zastosowano pierwsze młoty matrycowe, w czasie II wojny światowej zakład przejęła niemiecka firma Volkswagenwerk (1941r.) Zgodnie z zamierzeniami nowych właścicieli zakładu, miał on zostać jedną z największych kuźni w Europie.

1946 r.

Wykonany został w zakładzie prototyp silnika do polskiego motocykla “Sokół”.

1947 r.

Potwierdzono decyzję o przejęciu zakładu na własność państwa i nadano mu nazwę Przedsiębiorstwo Państwowe “Kuźnia Ustroń”. Wzrastające zapotrzebowanie na odkuwki, a także dbałość o zachowanie uzdrowiskowego charakteru miasta Ustroń wpłynęło na decyzję o niedokonywaniu dalszej rozbudowy zakładu w mieście.

1968 r.

Oddano do użytku nowy zakład w Skoczowie.

1970 r.

Zakłady w Skoczowie i w Ustroniu zostały włączone do Wytwórni Sprzętu Mechanicznego “Polmo”.

1972 r.

Zakłady Polmo, w tym kuźnie w Ustroniu i w Skoczowie zostały przekształcone w “Fabrykę Samochodów Małolitrażowych” w Bielsku – Białej, która na bazie licencji z firmą FIAT produkowała samochód Fiat 126 p. Odtąd obie kuźnie funkcjonowały już jako “FSM Zakład Nr 3” (Ustroń) i “FSM Zakład Nr 4” (Skoczów) z siedzibą w Skoczowie.

1990 r.

Przedsiębiorstwo państwowe FSM zostało przekształcone w Spółkę Akcyjną Skarbu Państwa.

1992 r.

Znaczna część Fabryki Samochodów Małolitrażowych S.A. została wniesiona w aporcie do nowo powstałej firmy “Fiat Auto Poland”. Z pozostałej części majątku FSM ( w tym również zakłady w Ustroniu i Skoczowie) utworzono spółkę Skarbu Państwa pod nazwą FSM Wytwórnia Wyrobów Różnych S.A.

1995 r.

Zakłady Kuźnicze uzyskały samodzielność organizacyjną i osobowość prawną – powstała spółka prawa handlowego pod nazwą “Zakłady Kuźnicze Spółka z o.o.” z siedzibą w Skoczowie, w skład której weszły dwa zakłady produkcyjne: w Ustroniu i w Skoczowie.

2002 r.

FSM WWR S.A zapoczątkował procedurę prywatyzacji – sprzedaży udziałów Zakładów Kuźniczych w drodze publicznej oferty.

2004 r.

FSM WWR S.A dokonał sprzedaży 100% udziałów Zakładów Kuźniczych spółce Kuźnia Polska Sp. z o.o.

2004 r.

Nastąpiło połączenie spółek Kuźnia Polska Sp. z o.o (spółka przejmująca) i Zakładów Kuźniczych Sp. z o.o. (spółka przejmowana).

2008 r.

Kuźnia Polska Sp. z o.o. została przekształcona w Kuźnię Polskę Spółkę Akcyjną.

2015 r.

Kuźnia Polska S.A. została przejęta przez grupę kapitałową Zetkama notowaną na Giełdzie Papierów Wartościowych, www.zetkamagroup.pl

2023 r.

1 czerwca 2023 KUŹNIA POLSKA SA przejmuje zakład MCS Sp. z o.o. w Żorach, który zmienia nazwę na Kuźnia Polska Oddział Żory

Zadzwoń do nas:

+48 (33) 85 48 283

+48 (33) 85 85 111